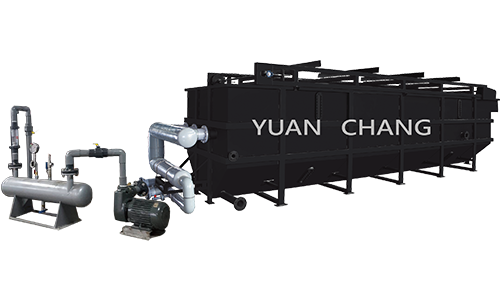

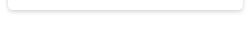

DAC Series (Circular barrel)

Machine outline diagram

Standard specifications (Contact for customized)

Spe. |

Model | |||||

|---|---|---|---|---|---|---|

| DAC-5 | DAC-10 | DAC-15 | DAC-20 | |||

| Treating capacity (m3/hr) Influent concentration (S.S 0.1~0.3%) |

3-5 | 7-10 | 12-15 | 17-20 | ||

| Concentrated sludge water content(%) | 1~3 | |||||

| Power usage (HP) | Mud dial driver (constant speed) |

1/2 | 1/2 | 1/2 | 1/2 | |

| Emulsified water pressurized pump(Optional) | Depends on the SS concentration of the water quality of the case | |||||

| Main tank body and air dissolution tank material | Standard | Contact parts SUS304 + externally reinforced SS400 + Epoxy Epoxy anti-corrosion treatment | ||||

| Optiooal | All stainless steel SUS304、SUS316 | |||||

| Referance dimension (mm) |

Floating tank | D (Φ) | 1180 | 1720 | 1970 | 2370 |

| H | 2625 | 3100 | 3220 | 3850 | ||

| Air soluble barrel | (Φ) x L | 200 x 1250 | 200 x 1250 | 250 x 1260 | 250 x 1260 | |

| W | 330 | 330 | 380 | 380 | ||

| H | 860 | 860 | 910 | 910 | ||

| Remarks: *The specifications are accepted outside the specification. and the company reserves the right to design changes. *Please ask for the actual installation dimension drawing before ordering. *The piping belongs to the on-site pipeline configuration project. |

Usages

|

*Wash water is filtered for recycling and reuse . *Solid/liquid separation of various industrial wastewater chemical coagulation treatments . *Separation of oil/water from oily wastewater treatment.. *he concentration treatment of the sludge effectively increases the concentration and reduces the treatment cost.. *For the treatment of sludge with a small specific gravity and a small site, the equipme characteristics of short residence time and strong floating ability, especially applicable. *The pulp of the paper mill is recycled and reused.. |