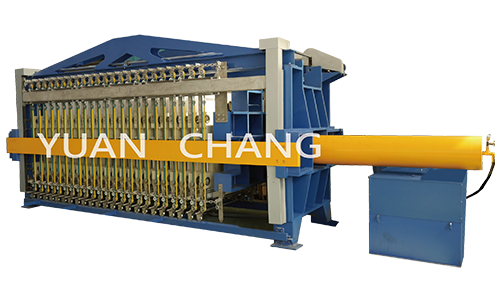

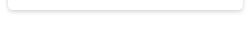

TE3 ( Conditioning + gravity filter belt thickening + double filter belt)→Triple filter belte

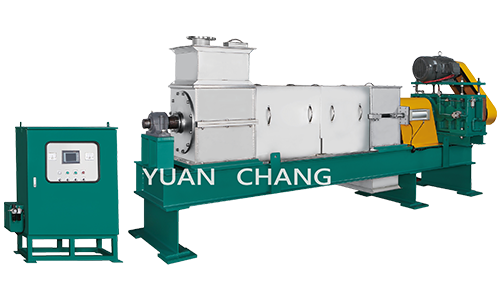

S.S. low / medium concentration

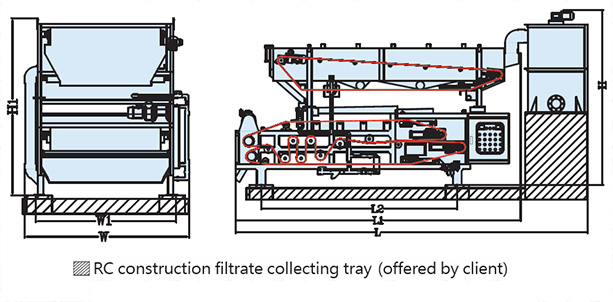

S.S. low / medium concentrationMachine outline diagram

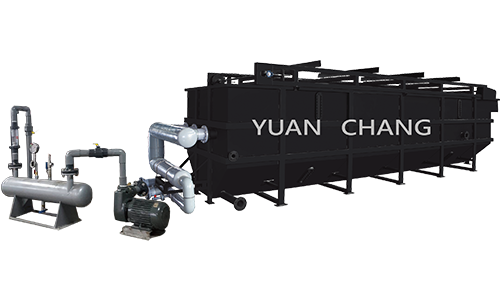

he Newest Super Water Saving, High-Pressure Reciprocating Type Washing System (Optional Accessory). It may completely substitute and solve the shortcomings of using the conventional type, save the huge cost of the treating recycling clean water of post-process. (Water saving rate:55~72%)

Standard specifications (Contact for customized)

| Spec. | Model | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| TE3-1000 | TE3-1250 | TE3-1500 | TE3-2000 | TE3-2000L | TE3-2500 | TE3-2500L | |||

| Belt width (mm) | 1000 | 1250 | 1500 | 2000 | 2000 | 2500 | 2500 | ||

| Low concentration (S.S 0.4~0.8%) |

Capacity (m3/hr) |

19~25 | 26~35 | 38~50 | 50~65 | 60~80 | 65~85 | 75~100 | |

| Absolute drynessD.S. (kg/hr) | 76~150 | 104~210 | 152~300 | 200~390 | 240~480 | 260~510 | 300~600 | ||

| Medium concentration (S.S 0.8~1.5%) |

Capacity (m3/hr) |

15.5~19 | 20.5~26 | 30.5~38 | 41~50 | 50~60 | 54~65 | 64~75 | |

| Absolute drynessD.S. (kg/hr) |

124~233 | 164~308 | 244~458 | 328~615 | 400~750 | 432~810 | 512~960 | ||

| Power usag (HP) | Belt driver (no step speed) |

1/2 | 1/2 | 1 | 1 | 2 | 2 | 3 | |

| Conditioning mixer | 1/4 | 1/2 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | ||

| Belt thickener (no step speed) |

1/2 | 1/2 | 3/4 | 3/4 | 1 | 1 | 1 | ||

| Machine material | Standard | Stainless steel SUS304 | |||||||

| Optional | Stainless steel SUS316 / 316L | ||||||||

| Referance dimension (mm) |

L | 4800 | 4900 | 5800 | 5900 | 7000 | 6300 | 7450 | |

| W | 1700 | 1950 | 2250 | 2800 | 3000 | 3350 | 3350 | ||

| H | 2800 | 2900 | 3100 | 3100 | 3500 | 3350 | 3650 | ||

| Referance weight (kgs) | 1750 | 2050 | 2800 | 3010 | 4300 | 4100 | 4700 | ||

| Remarks: * TE-1500 (including) and above models, TE3 full range of models are not equipped with the total drain pan under the filtrate. * TE3 full range of models with static mixing tube is standard. * The amount of treatment, the amount of dryness, and the moisture content of the cake (between 60 and 84%) depend on the type, concentration and characteristics of the sludge. * The specifications are accepted outside the specification, and the company reserves the right to design changes. * Please ask for the actual installation dimension drawing before ordering. * The cleaning pump (optional) needs to provide the best water pressure between 4.5 and 6.5kg/cm2 |