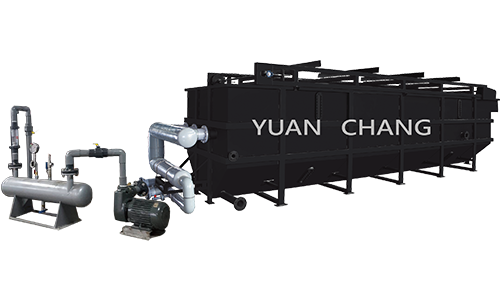

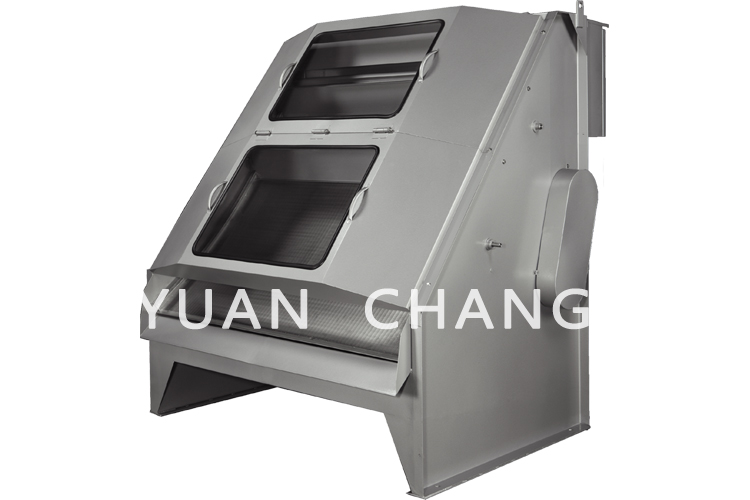

YU Series (Slant screen)

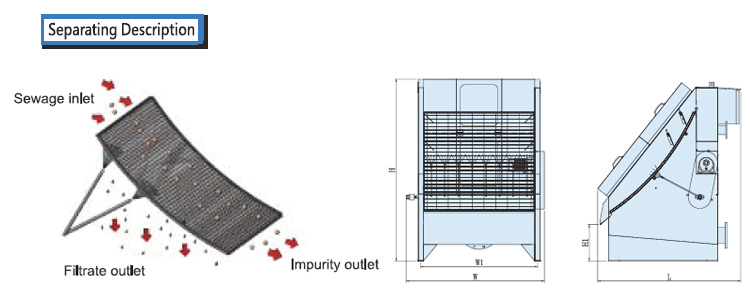

Machine outline diagram

Standard specifications (Contact for customized)

Spe. |

Model | ||||

|---|---|---|---|---|---|

| YU-70 | YU-130 | YU-190 | |||

| Capacity(water) (m3 /hr) |

Screen slit spacing (mm) |

1.0 | 33 | 70 | 110 |

| 1.5 | 42 | 90 | 130 | ||

| 2.0 | 48 | 100 | 150 | ||

| 3.0 | 60 | 130 | 200 | ||

| Power usage (HP) | standand | Washing drive | 1/2 | 1/2 | 1/2 |

| Optional | Washing pump | Power demand will vary depending on the spacing of the screen | |||

| Screw dawałem conveyor (Applicable to livestock, fibrous sludge) |

2 | 2 | 3 | ||

| Material | Standard | Stainless steel (SUS304) | |||

| Optional | Stainless steel (SUS316) Other special materials |

||||

| Referance dimension (mm) |

L | 1600 | 1600 | 1600 | |

| W | 1050 | 1550 | 2150 | ||

| H | 1960 | 1960 | 1960 | ||

| Referance weight (kgs) | 270 | 380 | 530 | ||

| Remarks: *The remarks are same as that of DR outer wheel screen. |

Usages

| *Hospital, community domestic sewage, urban sewer comprehensive treatment plant, printing and dyeing industry, textile industry, leather industry, paper industry, chemical industry, aquatic product

processing industry, food processing industry, meat processing industry, slaughtering industry, wine industry, sugar industry, etc. ... In the first stage of wastewater treatment, the scum and solid matter removal and fouling and solid and liquid separation projects are used. *The separation and treatment of floating matter and solid matter in the waste water of animal husbandry. *Recycling and recycling of raw materials in the paper and pulp industry. *Protect the wastewater treatment equipment (pump) to avoid foreign matter blockage |