Heat pump vacuum evaporator

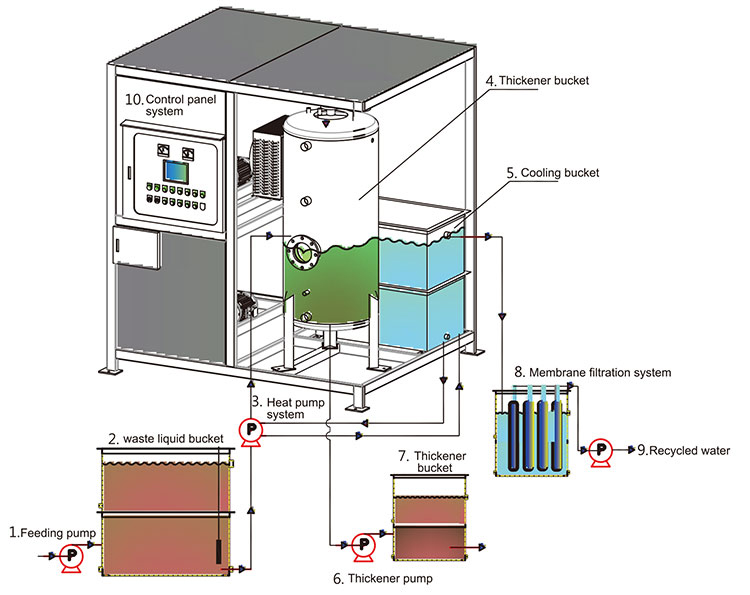

Machine outline diagram

Standard specifications (Contact for customized)

Spec. |

Model | |||||||

|---|---|---|---|---|---|---|---|---|

| CV25SS | CV-50SS | CV-25 | CV-50 | CV-100 | CV-150 | CV-200 | ||

| Capacity (L/hr) | 15~50 | 30~75 | 15~50 | 30-75 | 80-125 | 130-175 | 180-225 | |

| Power consumption of removing water (KWH/L) | 0.15-0.25 | |||||||

| Main body material | SS400 + Epoxy anti-corrosion treatment | SUS304 | ||||||

| Vacuum degree (mmHG) | - 700 ~ - 530 | |||||||

| Evaporation temperatur (°C) | 42 ~ 70 | |||||||

| Power usage (KW) | Compressor | 7.6 | 10.7 | 7.6 | 10.7 | 22.7 | 33.5 | 45.4 |

| Water-sealed vacuum pump | 2.25 | 5.6 | 2.25 | 5.6 | 5.6 | 7.5 | 7.5 | |

| Totalpower consumption (KWH) | 11.15 | 17.8 | 11.15 | 17.8 | 29.8 | 41.5 | 54.4 | |

|

Remarks:

* The amount of treatment varies with different oil quality and oil concentration. * The above specifications The company reserves the right to design changes * Please ask for the actual installation dimension drawing before ordering. |

Principle

|

* The main unit consists of a refrigerant compressor, a heat exchanger, and a vacuum pump. The concentrated waste liquid in the concentration tank is concentrated several times and stored in a concentrate tank. * Decompression distillation method is to automatically suck the waste liquid into the concentration tank, vaporize it by depressurization and low temperature boiling, and then turn it into condensed water through the cooling device * Using the working principle of the heat pump to heat the oil and water waste liquid, the vacuum pump draws a negative pressure to lower the boiling point and increases the evaporation amount. The ice water system condenses and evaporates the vapor to reduce the effect, and then filters and condenses the condensed water for reuse. * TRecycling of recycled water not only greatly reduces the total amount of waste liquid discharge, but also greatly reduces the cost of discharge treatment. At the same time, the reuse of condensed filtered water also saves water resources. |

Features

|

* Use a vacuum pump to draw waste liquid into the waste liquid heater. * The water-sealed vacuum pump vacuums the internal pressure of the concentrated barrel to a negative pressure. * Heat the concentrated barrel to a low temperature boiling temperature (42 ° C ~ 70 ° C). * Fully automatic and stable discharge of water quality is beneficial to “zero emission” and environmental protection. * Low-temperature vacuum distillation operation mode, equipment footprint is small, minimum operating cost, and COD value is greatly reduced * The condensed water can be passed through a membrane filtration device to recycle water. |