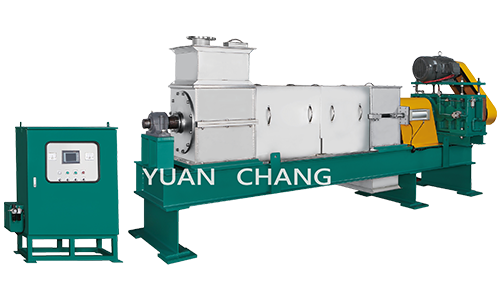

Vacuum evaporator concentrator equipment

- Home

- Products

- Industrial metal waste liquid and cutting waste liquid evaporation reduction processing equipment

-

Vacuum evaporator concentrator equipment

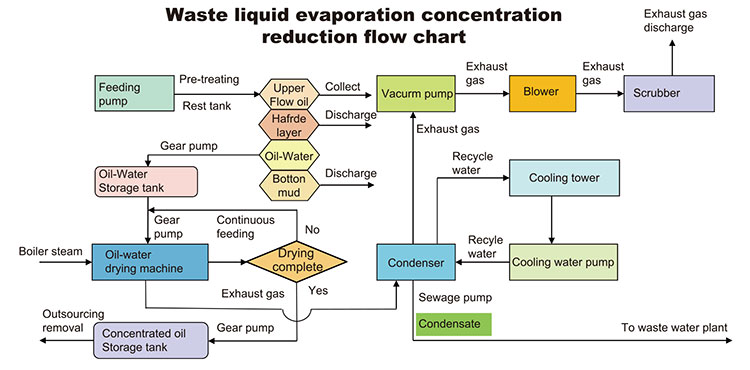

Processing flow chart (for reference only)

Standard specifications (Contact for customized)

Spec. |

Model | ||||||

|---|---|---|---|---|---|---|---|

| GCV-250 | GCV-500 | GCV-750 | GCV-1000 | GCV-1500 | GCV-250 | GCV-3000 | |

| Capacity (kg/hr) | 250 | 500 | 750 | 1000 | 1500 | 2000 | 3000 |

| Daily capacity (Ton/8hr) | 2 | 4 | 6 | 8 | 12 | 16 | 24 |

| Steamconsumption of removing water (Kg) | about 1.2 | ||||||

| Vacuum degree (mmHG) | -600 ~ -500 | ||||||

| Evaporation temperature (°C) | 52 ~ 73 | ||||||

| Reactor power (HP) | 2.5 | 5 | 7.5 | 10 | 15 | 20 | 30 |

| Water-sealed vacuum pump power (HP) | 5 | 10 | 15 | 20 | 30 | 40 | 60 |

|

Remarks:

* The amount of treatment varies with different oil quality and oil concentration. * The above specifications The company reserves the right to design changes * Please ask for the actual installation dimension drawing before ordering. |

Principle

|

* TEvaporation is a method of separation and purification, which includes two procedures of gasification and condensation. Evaporate the waste liquid to obtain sufficient energy to vaporize, condense through the condensation tube to discharge the condensate, and finally collect the evaporated concentrate. * Evaporation reduction is to automatically attract the waste liquid into the evaporation barrel, vaporize it by depressurization and low temperature boiling, and then make it into condensed water through the cooling device. * The advantage of vacuum evaporation is that it can be prevented from decomposing when heated at high temperatures. In addition, the required temperature is lower, and a lower temperature heat source can be used, which is safer and more energy efficient. |

Features

|

* Use a vacuum pump to draw waste liquid into the waste liquid to heat the drying concentrator. * The water-sealed vacuum pump draws vacuum to reduce the internal pressure of the concentrated barrel to a negative pressure. * Heat the concentrated barrel to a low temperature boiling temperature (52 ° C ~ 73 ° C). * Automatically and stably discharge water quality, which is beneficial to “zero emission” and environmental protection. * Low-temperature vacuum distillation operation mode, low operating cost of equipment, and greatly reduced COD value. |

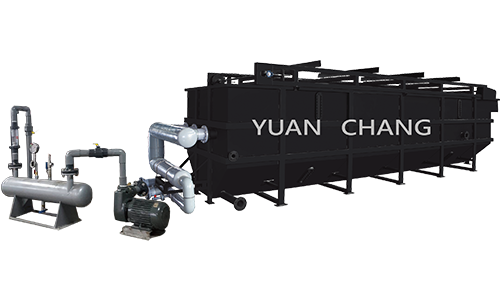

Total usages

|

* Metal processing cutting oil and water waste liquid concentration reduction. * Surface treatment, electroplating wastewater waste liquid concentration reduction. * Degreasing, leather industry, dyeing and finishing industry waste liquid concentration reduction. * Water-soluble paint, varnish washing, dampening water waste liquid concentration reduction. * Concentration of food processing waste liquid, chemical wastewater, and papermaking wastewater. * Inorganic and organic wastewater of organic pollutants and mixed wastewater containing inorganic substances. |