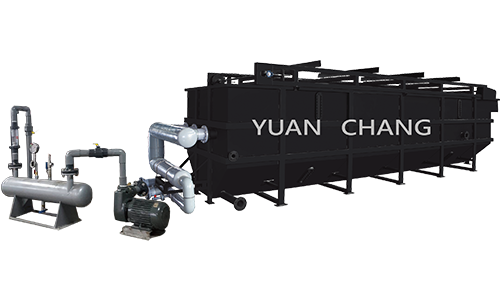

KC Series (tower disc-continuous processing)

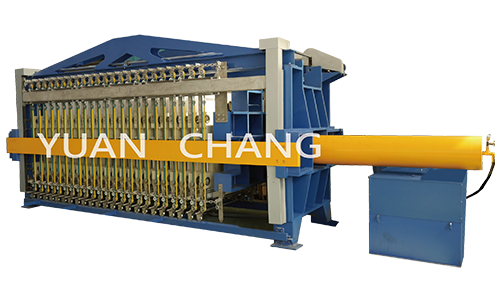

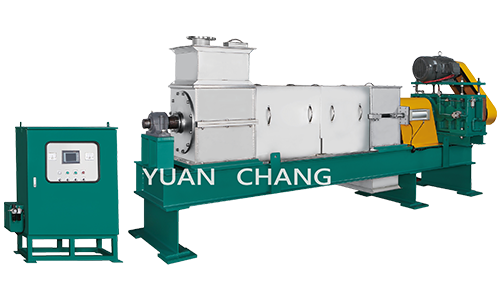

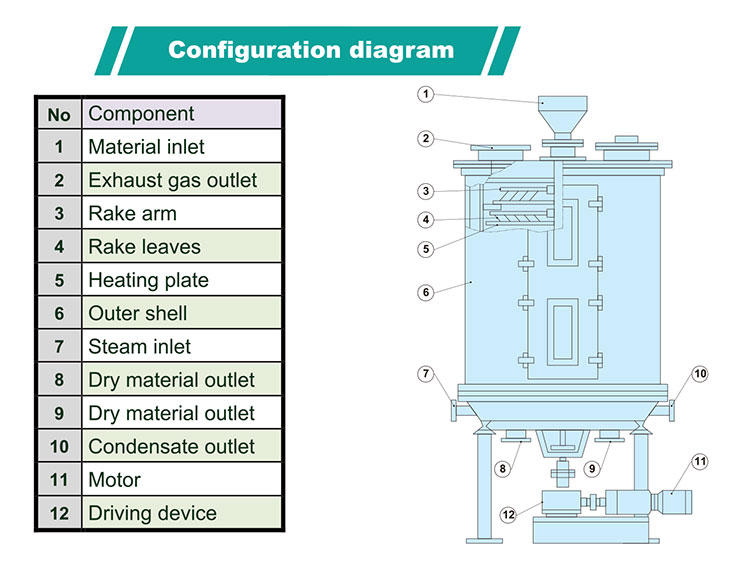

Machine outline diagram

Standard specifications (Contact for customized)

Spec. |

Model | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| KC-200 | KC-300 | KC-400 | KC-500 | KC-750 | KC-1000 | KC-1500 | KC-2000 | ||

| Capacity kg/hr (85%→40%) |

200 | 300 | 400 | 500 | 750 | 1000 | 1500 | 2000 | |

| Daily capacity ton/24hr (85%→40%) |

4.8 | 7.2 | 9.6 | 12 | 18 | 24 | 36 | 48 | |

| Sludge classification | Organic / inorganic | ||||||||

| Heat source | Steam / hot air | ||||||||

| Highest treatable moisture content (%) | 85 (depending on sludge type and moisture content) | ||||||||

| Drying temperature (℃) | 100 ~ 180 (depending on sludge type and moisture content) | ||||||||

| Reference dimension of dry towe (mm) | Ф | 1200 | 1200 | 1200 | 1400 | 1400 | 1500 | 1800 | 2000 |

| H | 3500 | 3500 | 3500 | 3500 | 5000 | 5000 | 5000 | 6500 | |

| Layer | 4 | 6 | 8 | 8 | 10 | 10 | 10 | 12 | |

| HP | 3 | 3 | 5 | 5 | 7.5 | 7.5 | 12.5 | 15 | |

| Required space (m×m) | 6x6 | 6x6 | 6x6 | 8x8 | 8x8 | 10x10 | 12x12 | 14x14 | |

Remarks:

|

USAGES

|

* Drying of organic and inorganic waste in industrial plants. * Inorganic sludge and biological sludge drying in factory wastewater treatment plant. * Industrial wastewater treatment: inorganic sludge in chemical coagulation sedimentation tank and biological sludge in secondary sedimentation tank. * The primary sedimentation tank of urban domestic sewage treatment plant contains sand sludge, secondary sedimentation tank biological sludge, and final sedimentation tank biological sludge (organic) drying. * Dry treatment of chemical sludge, electroplating sludge, dyeing and finishing sludge, leather sludge, papermaking sludge, boiler soot, urban domestic sludge, kitchen sludge, industrial sludge, metal waste, etc. * Residues from the pharmaceutical industry, residues from the sugar factory, residues from the monosodium glutamate factory, distiller's grains, bean residue, and other food and pharmaceutical industry residues. |