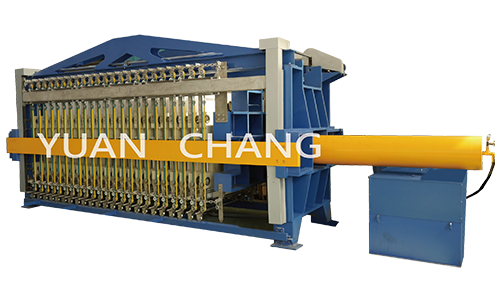

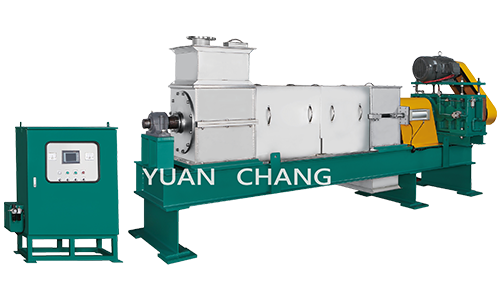

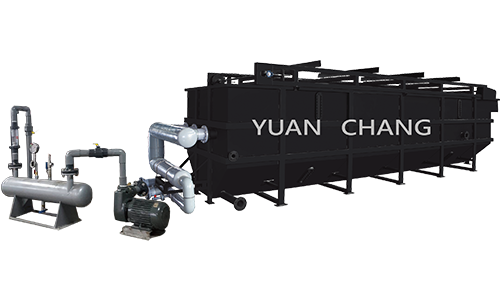

SR Series (Volute type - continuous process)

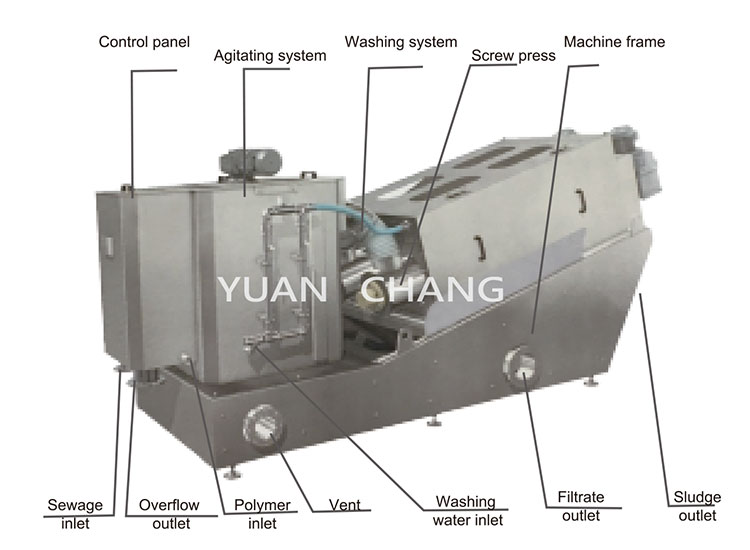

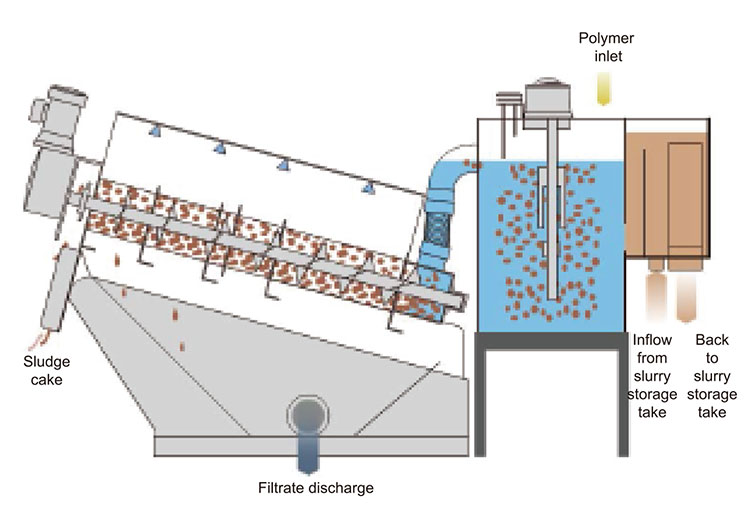

Machine outline diagram

Machine outline diagram

Standard specifications (Contact for customized)

| Model | Absolute dry capacity(Ds.kg /hr) (Limited influent concentration1~2.5% D.S) | Power usage(KW) | Cleaning water consumption(L/hr) (Pressure>2 kg/cm2 ) | Reference dimension(mm) | Reference weight (kgs) | |||

|---|---|---|---|---|---|---|---|---|

Driving motor KW x N |

Conditioning mixer KW x N |

L | W | H | ||||

| SR-131 | 5-10 | 0.18 x 1 | 0.18 x 1 | 43 | 1870 | 730 | 1170 | 250 |

| SR-251 | 15-30 | 0.55 x 1 | 0.37 x 1 | 58 | 2690 | 880 | 1600 | 500 |

| SR-301 | 30-60 | 0.75 x 1 | 0.55 x 1 | 93 | 3310 | 1000 | 1700 | 750 |

| SR-303 | 90-180 | 0.75 x 3 | 0.75 x 1 | 279 | 3700 | 1650 | 1850 | 1750 |

| SR-351 | 50-180 | 1.1 x 1 | 0.75 x 1 | 126 | 3610 | 1100 | 1850 | 1150 |

| SR-352 | 100-200 | 1.1 x 2 | 0.75 x 1 | 252 | 3820 | 1490 | 2250 | 1950 |

| SR-401 | 80-160 | 1.5 x 1 | 1.5 x 1 | 115 | 4550 | 1180 | 2250 | 2050 |

| SR-402 | 160-320 | 1.5 x 2 | 1.5 x 1 | 230 | 4870 | 1710 | 2250 | 3850 |

| SR-403 | 240-480 | 1.5 x 3 | 1.5 x 2 | 345 | 4790 | 2550 | 2250 | 5400 |

| SR-404 | 320-640 | 1.5 x 4 | 1.5 x 2 | 460 | 4840 | 3140 | 2250 | 7000 |

|

Remarks:

* If the sewage concentration is less than 10000mg/L, it is recommended to carry out sedimentation and concentration treatment; if the sewage concentration is greater than 25000mg/L, it is recommended to carry out dilution treatment. * The specifications are accepted outside the specification, and the company reserves the right to design changes. * Please ask for the actual installation dimension drawing before ordering. |

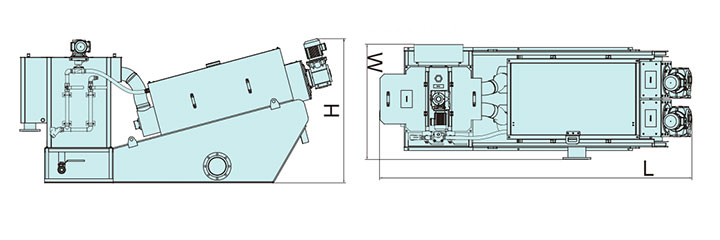

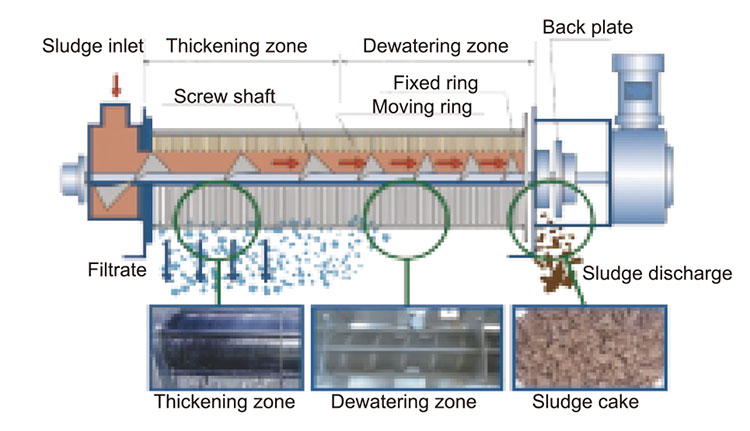

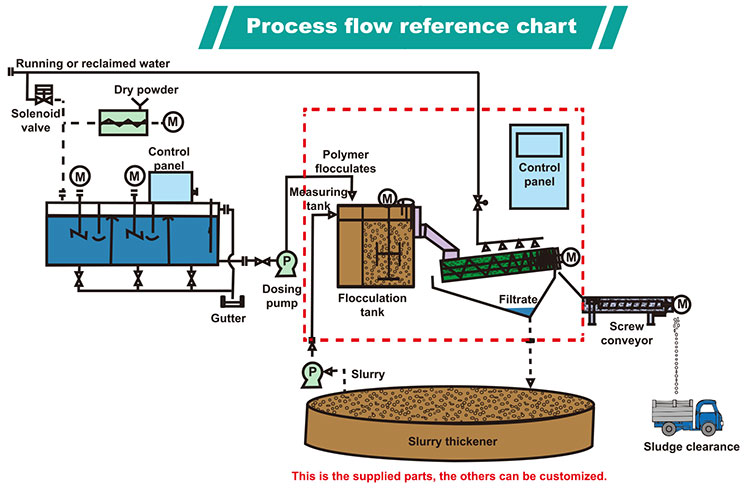

Features

|

* Unique design, the filter hole will never be blocked. * The structure is streamlined and saves space. * low energy consumption, less water cleaning. * Clean, environmentally friendly, non-polluting, easy to maintain. * Simple processing, high efficiency in dewatering, low system investment * System can be programmed to make the operation more convenient and accurate. * Unique flocculating agent make sludge dewatering easier. * Uniform and accurate dispensing, saving costs * Strong ability to resist oily sludge, the best oil sludge dewatering machine. |

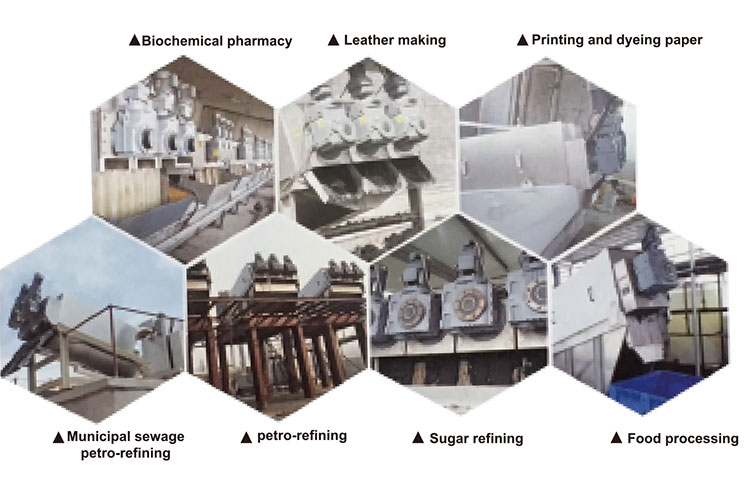

Application industry

|

* Applications: municipal sewage, petro-refining, leather making, printing and dyeing, paper making, welding material, coal beneficiation, biochemical pharmacy, steel pickling, chemicals, sugar making, food and drinks processing…etc. |