CD Series (low temperature dehumidification - continuous treatment)

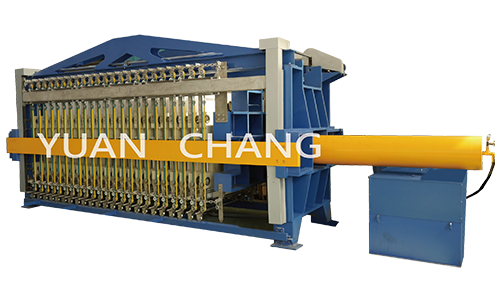

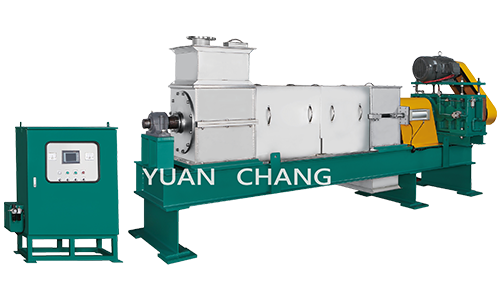

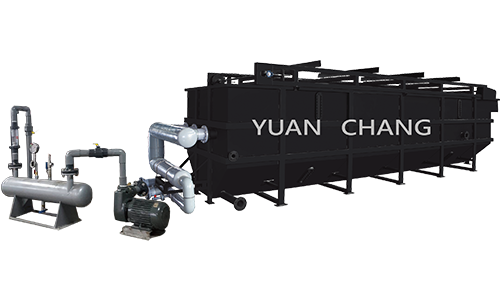

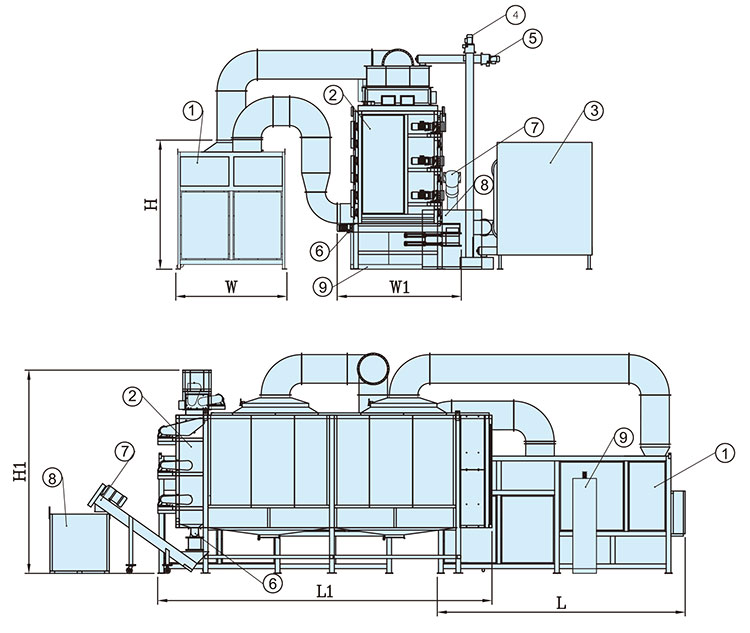

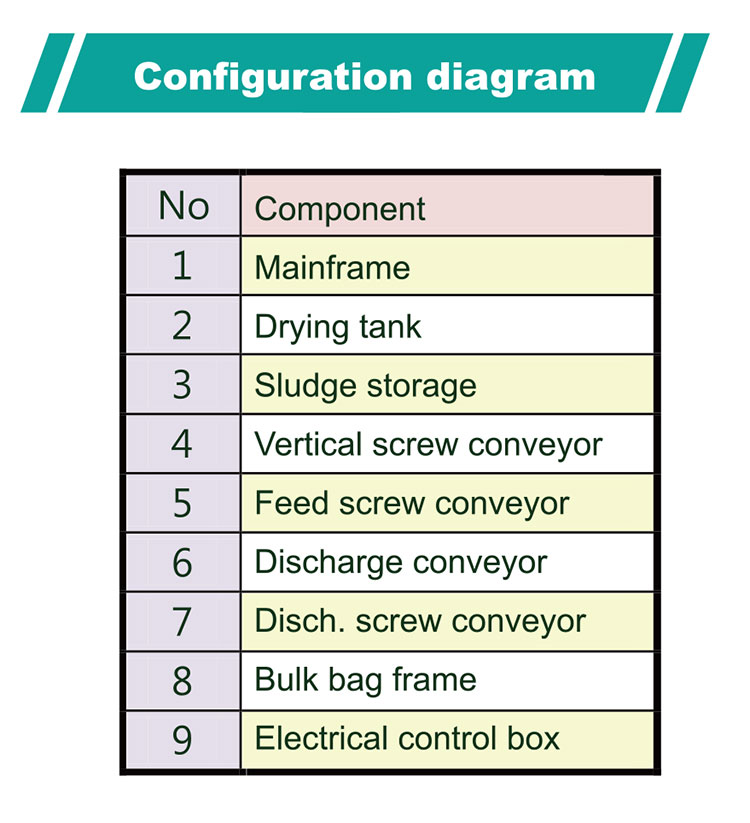

Machine outline diagram

Standard specifications (Contact for customized)

Spec. |

Model | |||||||

|---|---|---|---|---|---|---|---|---|

| CD-100 | CD-200 | CD-300 | CD-400 | CD-500 | CD-750 | |||

| Capacity L/hr (85%/75%→40%) |

100 | 200 | 300 | 400 | 500 | 750 | ||

| Daily capacity M3/24hr (85%/75%→40%) |

2.4 | 4.8 | 7.2 | 9.6 | 12 | 18 | ||

| Sludge classification | Organic / inorganic | |||||||

| Electricity consumption (KWH) / kg | 0.3 ~ 0.55 (water content 75% ~ 85% to 40%,depending on sludge type and moisture content | |||||||

| Highest treatable moisture content (%) | 85 (depending on sludge type and moisture content) | |||||||

| Drying temperature (℃) | 35 ~ 70 (depending on sludge type and moisture content) | |||||||

| Reference dimendion (mm) |

Main frame | L | 3600 | 4600 | 4600 | 4600 | 5200 | 5200 |

| W | 2000 | 2100 | 2100 | 2100 | 2400 | 2400 | ||

| H | 2300 | 2300 | 2300 | 2300 | 2700 | 2700 | ||

| Dry Tank | L | 4000 | 4200 | 5200 | 6200 | 7200 | 10000 | |

| W | 2600 | 2500 | 2500 | 2500 | 2500 | 2500 | ||

| H | 3700 | 4400 | 4400 | 4400 | 4400 | 4400 | ||

| Numer of mainframe | 1 | 1 | 1 | 2 | 2 | 3 | ||

| Required space (m×m) | 8×3 | 8x4 | 8x5 | 10×6 | 10×8 | 12x8 | ||

Spec. |

Model | ||||||

|---|---|---|---|---|---|---|---|

| CD-1000 | CD-1500 | CD-2000 | CD-3000 | CD-4000 | |||

| Capacity L/hr (85%/75%→40%) |

1000 | 1500 | 2000 | 3000 | 4000 | ||

| Daily capacity M3/24hr (85%/75%→40%) |

24 | 36 | 48 | 72 | 96 | ||

| Sludge classification | Organic / inorganic | ||||||

| Electricity consumption (KWH) / kg | 0.3 ~ 0.55 (water content 75% ~ 85% to 40%,depending on sludge type and moisture content | ||||||

| Highest treatable moisture content (%) | 85 (depending on sludge type and moisture content) | ||||||

| Drying temperature (℃) | 35 ~ 70 (depending on sludge type and moisture content) | ||||||

| Reference dimendion (mm) |

Main frame | L | 5200 | 5200 | 5200 | 5200 | 5200 |

| W | 2400 | 2400 | 2400 | 2400 | 2400 | ||

| H | 2700 | 2700 | 2700 | 2700 | 2700 | ||

| Dry Tank | L | 12000 | 18000 | 24000 | 36000 | 48000 | |

| W | 2500 | 2500 | 2500 | 2500 | 2500 | ||

| H | 4400 | 4400 | 4400 | 4400 | 4400 | ||

| Numer of mainframe | 4 | 6 | 8 | 12 | 16 | ||

| Required space (m×m) | 14x10 | 21x10 | 26x10 | 38x10 | 50 x10 | ||

Remarks:

|

Usages & features

| * The best drying and reducing system for organic sludge and inorganic sludge * Dry processing of agricultural products and livestock products (please inquire separately) * Dry materials in the pharmaceutical, food, chemical and other industries (please contact us separately) * Widely used in metallurgical additives, chemicals, food, packaging and other fields. * Dry materials in the pharmaceutical, food, chemical and other industries (please contact us separately) * The equipment has compact structure, small floor space, simple operation, convenient maintenance and stable operation. * With the ability of large production, high efficiency, energy saving and continuous production. * Low-temperature dehumidification and drying energy consumption is low, no waste gas and dust are generated, and there is no secondary pollution. |