CDB Series-Low temperature dehumidification type drying system (batch treating)

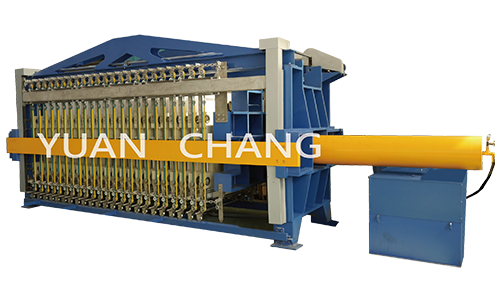

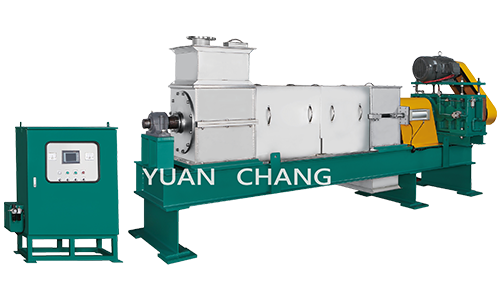

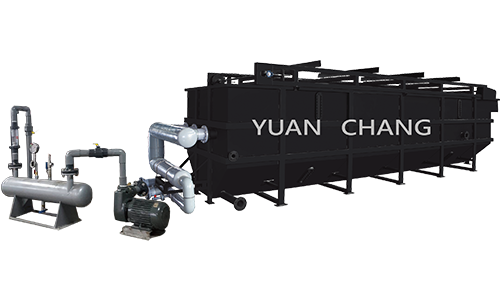

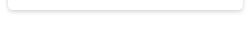

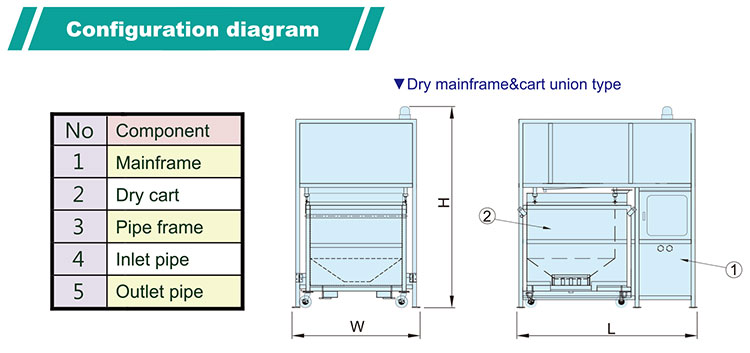

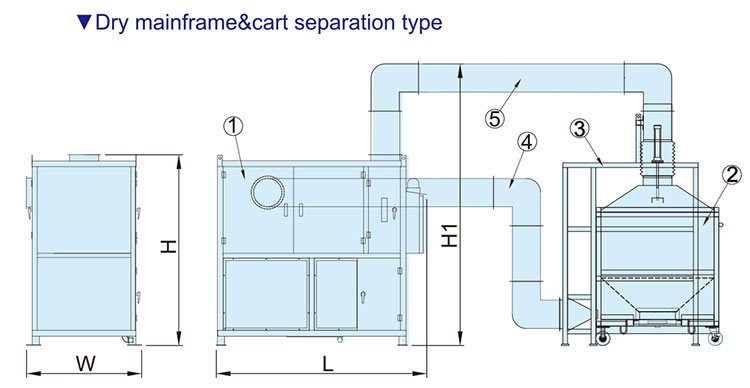

Machine outline diagram

Standard specifications (Contact for customized)

Spec. |

Model | ||||||

|---|---|---|---|---|---|---|---|

| CDB-200U | CDB-300U | CDB-500U | CDB-750U | CDB-1000U | |||

| Bath capacity L/24hr (75%→40%) |

200 | 300 | 500 | 750 | 1000 | ||

| Sludge classification & sources | Organic (depending on actual test) / inorganic: Sludge cake after dewatering using a filter press / belt filter / volute / screw press / centrifuger |

||||||

| Electricity consumption (KWH) / kg | 0.3 ~ 0.55 (water content 75% ~ 85% to 40%,depending on sludge type and moisture content)) | ||||||

| Drying temperature (℃) | 35 ~ 70 (Depending on sludge type and moisture content) | ||||||

| Reference dimension (mm) |

Main machine | L | 2250 | 2400 | 2400 | 2400 | 2430 |

| W | 1350 | 1350 | 1540 | 1540 | 1800 | ||

| H | 2200 | 2320 | 2420 | 2420 | 2450 | ||

| Drying car | L | 950 | 1050 | 1100 | 1200 | 1300 | |

| W | 900 | 1000 | 1100 | 1200 | 1300 | ||

| H | 900 | 1020 | 1120 | 1130 | 1300 | ||

| Space required (m×m) | 3 x 2.5 | 3 x 3 | 3 x 3 | 3 x 3 | 3.5 x 3.5 | ||

Spec. |

Model | ||||||

|---|---|---|---|---|---|---|---|

| CDB-500 | CDB-750 | CDB-1000 | CDB-1500 | CDB-2000 | |||

| Batch capacity L/24hr (75%→40%) |

500 | 750 | 1000 | 1500 | 2000 | ||

| Sludge classification & sources | Organic (depending on actual test) / inorganic: Sludge cake after dewatering using a filter press / belt filter / volute / screw press / centrifuger |

||||||

| Electricity consumption (KWH) / kg | 0.3 ~ 0.55 ((water content 75% ~ 85% to 40%,depending on sludge type and moisture content) | ||||||

| Drying temperature (℃) | 35 ~ 70 (Depending on sludge type and moisture content) | ||||||

| Reference dimension (mm) |

Main machine | L | 2250 | 2250 | 2250 | 3000 | 3000 |

| W | 1220 | 1220 | 1220 | 1650 | 1700 | ||

| H | 2000 | 2000 | 2170 | 2310 | 2310 | ||

| Drying cart/tank | L | 1230 | 1280 | 1300 | 1500 | 1300 | |

| W | 1170 | 1280 | 1300 | 1500 | 1300 | ||

| H | 1130 | 1130 | 1340 | 1750 | 1340 | ||

| H1 | 2900 | 2900 | 2900 | 3270 | 2900 | ||

| Space required (m×m) | 4 x 4 | 4 x 4 | 4 x 4 | 6 x 6 | 8 x 8 | ||

Spec. |

Model | |||||

|---|---|---|---|---|---|---|

| CDB-3000 | CDB-3000T | CDB-4000T | CDB-5000T | |||

| Batch capacity L/24hr (75%→40%) |

3000 | 3000 | 4000 | 5000 | ||

| Sludge classification & sources | Organic (depending on actual test) / inorganic: Sludge cake after dewatering using a filter press / belt filter / volute / screw press / centrifuger |

|||||

| Electricity consumption (KWH) / kg | 0.3 ~ 0.55 ((water content 75% ~ 85% to 40%,depending on sludge type and moisture content) | |||||

| Drying temperature (℃) | 35 ~ 70 (Depending on sludge type and moisture content) | |||||

| Reference dimension (mm) |

Main machine | L | 3620 | 3620 | 4600 | 4600 |

| W | 1900 | 1900 | 2100 | 2100 | ||

| H | 2450 | 2450 | 2450 | 2450 | ||

| Drying cart/tank | L | 1500 | 2300 | 2500 | 2800 | |

| W | 1500 | 1750 | 2000 | 2200 | ||

| H | 1750 | 2300 | 2500 | 2800 | ||

| H1 | 3960 | 3960 | 3500 | 3700 | ||

| Space required (m×m) | 8 x 8 | 8 x 8 | 8 x 8 | 8 x 8 | ||

Remarks:

|

Usages

| * Applicable to the drying reduction of sludge cake after dehydration of various industrial sludges (inorganic). * The volume of sludge after drying is reduced by 40%, the weight by more than 70%, and the treatment cost is effectively reduced. * The electricity consumption is only 0.4~0.6 degrees per kilogram of dewatering. It can also be used in the off peak electricity price period to operate with high economic benefits. * Closed circulation, low noise, no waste water, waste gas, no secondary pollution problems. |

features

| * The volume of sludge after drying is reduced by 50%, the weight by more than 60%, and the treatment cost is effectively reduced. * The electricity consumption is only 0.3~5.5 degrees per kilogram of dewatering. It can also be used in the off peak electricity price period to operate with high economic benefits * Closed circulation, low noise, no waste water, waste gas, no secondary pollution problems. * Patent certificate number: new type M585786. |

Drying Treatment Examples (For Reference Only)