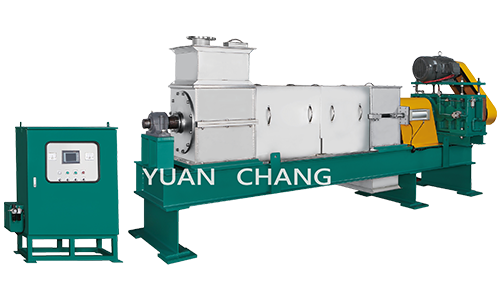

SY2 Series (Twin screw heavy load type) screw extrusion dewatering machine

|

The main feature of this model:

For materials that are particularly difficult to squeeze, because the single-screw type is easy to produce the axle, the material cannot be pushed forward, and the equipment will not be used. The company has developed a double-spiral type. It can be used for materials that are particularly difficult to handle, such as fish oil and fish. Pulp, meat quality, potato skin, feed, beets, etc... are especially suitable |

Standard specifications (Contact for customized)

Spec. |

Model | ||||||

|---|---|---|---|---|---|---|---|

| SY2-15 | SY2-20 | SY2-305 | SY2-40 | SY2-50 | SY2-60 | ||

| Capacity (M3/hr) | 0.5~1.0 | 1.0~2.5 | 2.0~6.0 | 5.0~12 | 10~25 | 20~40 | |

| Drive power (HP) | 3~5 | 7.5~10 | 10~15 | 20~25 | 30~50 | 40~75 | |

Reference dimension (mm) |

L | 3100 | 3600 | 4500 | 5400 | 6300 | 7100 |

| W | 1150 | 1250 | 1350 | 1500 | 1650 | 1800 | |

| H | 1750 | 1800 | 1900 | 2000 | 2000 | 2100 | |

| Reference weight (kgs) | 2200 | 3000 | 3600 | 5400 | 7600 | 10500 | |

|

Remarks:

* The amount of treatment and water content vary depending on the physical properties, type and solid content. * The driving horsepower and the amount of processing will vary depending on the type of physical property * The specifications are accepted outside the specification, and the company reserves the right to design changes |

Features

| * The SY2 spiral step-by-step extruder is a press separation device that can be continuously operated for the extrusion of liquids from organic materials and the separation of inorganic materials and slag. The separator belongs to the design and change of the most advanced screw extruder. * The screen is not clogged and there are no special requirements for feed concentration, viscosity, enthalpy, and particle size and fiber length * The press can run stably and smoothly, the failure rate is low, the operation and maintenance cost is low, and the extremely high dehydration rate is its main feature. The dryness of some materials after dehydration reaches 40%, which is difficult to achieve by ordinary presses or dewatering machines. , bringing considerable economic benefits to waste recycling. * It is especially suitable for assembly line operations, which avoids the disadvantages of ordinary presses requiring centralized processing.The complex materials for the slag are not afraid of wear and tear, and the effluent is smooth. The main purpose is to achieve the purpose of press separation due to the effective cooperation between the spiral and the screen. * The extrusion separator successfully solves the problem of screen clogging. The core technology is the cooperation of the screw and the screen to realize the self-cleaning function of the screen. The special device and the spiral realize the interaction to stir the animal material, and avoid the material to hold the shaft. Second, the material realizes that the material particles squeeze out the blockage of the screen during the spiral forward advancement process. * The tail outlet end control is different from the common springs, hydraulics, handwheels, etc. on the market, and the pneumatic device with extremely low maintenance cost is used to effectively realize the “back pressure” control of the material pressing through a specific design, that is, setting a certain After the pressing pressure, the device automatically realizes the control of the pressing force of the material to avoid the slag drying and wetting. At the same time, the extrusion separator is especially suitable for the assembly line because of the sequential compression principle, which avoids the need for the common press to concentrate. Disadvantages of handling. |

Usages

| * The juice of fruits and vegetables and the roots, stems, leaves and fruits are hydraulically pressed. * Food processing solid-liquid separation and crushing dewatering of waste residue: glutinous rice distiller's grains, seafood waste, various Chinese medicine slag, various tea slag, vinegar grains, beer slag, coffee grounds, corn husk, furfural residue, fish paste, shrimp residue, chicken feather chicken slag and so on * Energy and material processing solid-liquid separation and crushing and dewatering of waste residue: biogas slag, sweet sorghum, oil residue, etc. * Press and dehydrate the fruits and vegetables, kitchen waste, domestic |