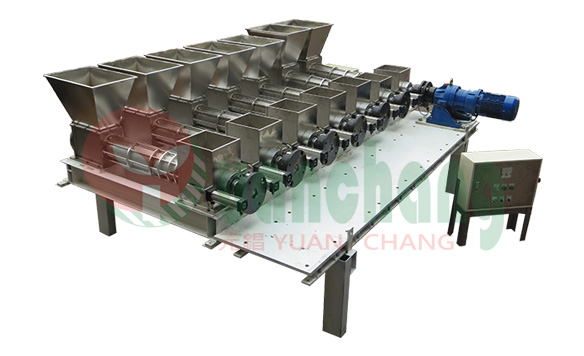

| Model\ Spec | SY-20 | SY-30 | SY-40 | SY-50 | SY -60 | SY-80 | SY-100 | SY-120 | |

| Treating Capacity (M³/hr) Inlet Consistency(S.S.5~10%) |

2.5~6 | 3.5~9 | 5~12 | 7~15 | 8~18 | 12~24 | 15~30 | 18~36 | |

Driving Motor Power (HP) |

3~7.5 | 5~10 | 7.5~15 | 15~25 | 20~30 | 50~75 | 100~150 | 150~250 | |

| External Dimensions (reference)(mm) | L | 3160 | 3760 | 4770 | 5800 | 6800 | 9100 | 10700 | 12300 |

| W | 1150 | 1230 | 1350 | 1500 | 1650 | 1950 | 2150 | 2350 | |

| H | 1140 | 1230 | 1340 | 1420 | 1680 | 2050 | 2250 | 2450 | |

| Reference Weight(kg) | 1330 | 1700 | 3000 | 4600 | 6200 | 12700 | 16500 | 21100 | |

|

Remarks: The treating capacity and water content’s rate will be changed with the physical properties, slurry types and inlet consistence. The driving motor power will be changed with the physical properties and slurry types and inlet consistence The above data is for high-fiber, high-ash waste properties. Yuan Chang reserves the modification right of the above specifications. |

|

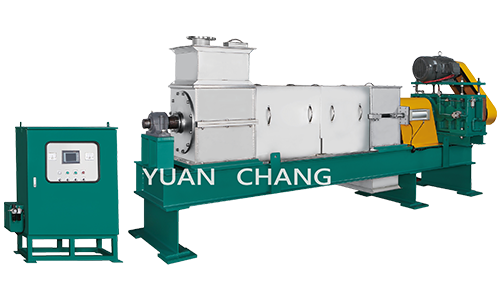

*Food industry rosacea, coffee grounds, Chinese medicine dregs, vegetables and fruits, food residue, aquatic processing extrusion dehydration. *Dehydration of dregs / fibrous / granular and other related substances for food industry, agricultural processing, fish processing, chemical, paper pulp, textile fibers, and slaughtering industry. *Extrusion processing broken or crushed uncooked or cooked material. *Tomatoes, apples, grapes, oranges, pineapples and other fruits squeezed into juice. *Agricultural fibrous, particulate matter and other related dehydration *Soy sauce and wine after fermentation extrusion manufacturing. *Palm oil, coconut oil extrusion manufacturing. *Squeeze manufacturing of all kinds of edible vegetable oils. *Dehydration for pulp sludge, dyeing fiber sludge, leather sludge, city sewer sludge, civil muck, livestock fecal residue, and slaughtering sludge. |

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

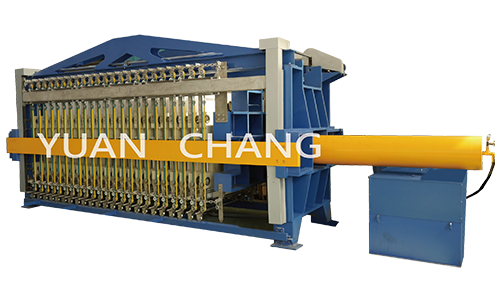

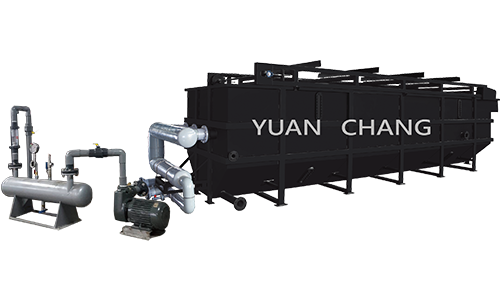

*Continuously dehydrating treatment to obtain more slurry treating volume and more steady solid content’s rate. *With washing function design, the filter net intermittent washing when running and filter net washing system before finish the above operation, to reduce the filter net blocking, less washing water consumption. *With intermittent or continuous operation, steady output, high efficient function, low power consumption due to low driving speed. *With coaxial deceleration operation, direct connection type driving design, high torque, low noise, less vibration, low wear out and low operating costs. *With close structure design, no pollution; gas collecting channel and hood are available. *Adopted Archimedes screw principle and screw arrangement design for various treating properties to get the better treating capacity, low water content’s rate of the residue cake and stable result. *Adopted stainless steel (SUS304) wedge wire screen and drilled metal mesh with high structure strength, wear resisting, durable, corrosion resisting, long using life span, good filtration and suitable filter opening rate to avoid to be clogged by the impurity. Good filtration matches material properties for maximum performance. *With patent outlet design, the internal fixed pressure would not have synchronous rotation problem. *Can be installed through steam heating or electric heater to reduce the water content rate and increase the treating capacity (Optional equipment). |

|

ⒶScrew rod outer diameter with tungsten carbide and hard chrome plating screw rod compression ratio designed by the geometric changes of it’s physical properties of the treated material, high transport efficiency of extrusion, abrasion resistance and long service life. ⒷDouble thrust bearing centralized face to face design, machine reaction force uniform, may increase bearing life and no vibration, no abnormal noise, direct drive of reducer and screw rod, with high torque and transmission efficiency. ⒸTapered hole in the outer filter design with high drainage rate, low clogging. ⒹThe feeding hopper, support net, filter net and discharged hopper are two haves designed, easy maintenance and installation, small disassembling job area. ⒺElectric control with touch human-machine interface, user operation, the historical data record, the parameters setting are user-friendly design. ⒻBack pressure ring made from engineering plastic, long life and low friction, three point support cylinder pressed, stable output with high solid content’s rate.。 |