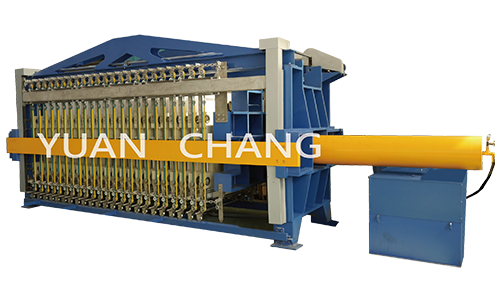

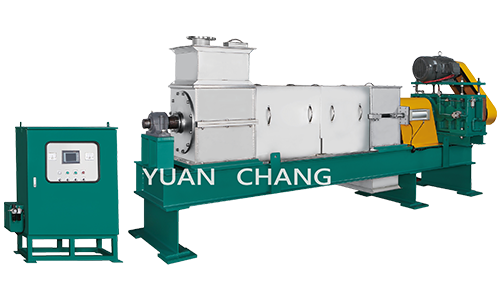

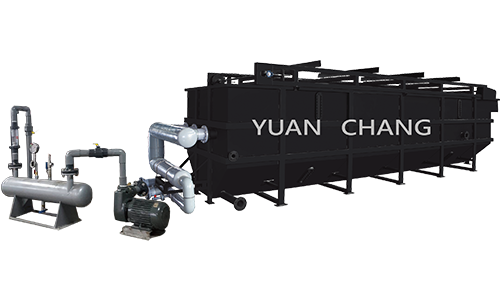

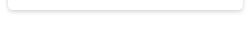

TE3 Conditioning + Gravity belt thickening + Double-belt → Triple-belt type

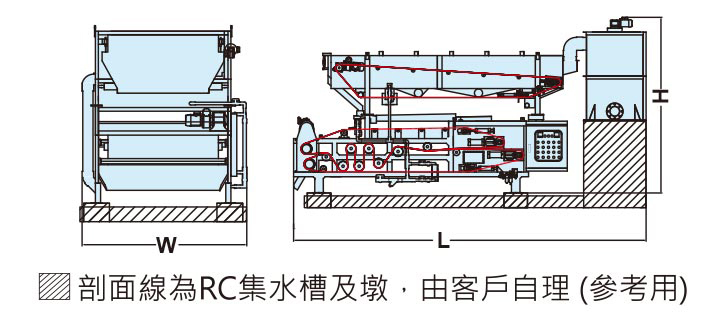

Machine outline diagram

Suitable for low / middle consistency

| Model | TE3-750 | TE3-1000 | TE3-1250 | TE3-1500 | TE3-2000 | |

| Belt Width (mm) | 750 | 1000 | 1250 | 1500 | 2000 | |

| Low Consistency (S.S. 0.4 ~ 0.8%) |

Treating Capacity (m3/hr) | 15 ~ 20 | 19 ~ 25 | 26 ~ 35 | 38 ~ 50 | 50 ~ 65 |

| D.S. (kg/hr) | 60 ~ 120 | 76 ~ 150 | 104 ~ 210 | 152 ~ 300 | 200 ~ 390 | |

| Middle Consistency (S.S. 0.8 ~ 1.5%) |

Treating Capacity (m3/hr) | 12 ~ 15 | 15.5 ~ 19 | 20.5 ~ 26 | 30.5 ~ 38 | 41 ~ 50 |

| D.S. (kg/hr) | 96 ~ 180 | 124 ~ 233 | 164 ~ 308 | 244 ~ 458 | 328 ~ 615 | |

| Power Consumption(HP) | Driving Motor (Speed Variable) | 1/2 | 1/2 | 1/2 | 1 | 1 |

| Disposal Agitator Motor | 1/4 | 1/4 | 1/2 | 3/4 | 3/4 | |

| Drum Thickener | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | |

| External Dimensions (Reference)(mm) | L | 4750 | 4800 | 4900 | 5800 | 5900 |

| W | 1500 | 1700 | 1950 | 2250 | 2800 | |

| H | 2800 | 2800 | 2900 | 3100 | 3100 | |

| Base Dimension L1×H1 (mm) | 4000 x 2400 | 4000 x 2400 | 4000 x 2400 | 4750 x 2500 | 4750 x 2500 | |

| Base Dimension L2×W1 (mm) | 2578 x 1160 | 2578 x 1410 | 2578 x 1660 | 3350 x 1940 | 3350 x 2440 | |

| Reference Weight (kgs) | 1500 | 1750 | 2050 | 2800 | 3350 | |

| Model | TE3-2500 | TE3-2000L | TE3-2500L | TE3-3000 | |

| Belt Width (mm) | 2500 | 2000 | 2500 | 3000 | |

| Low Consistency (S.S. 0.4 ~ 0.8%) |

Treating Capacity (m3/hr) | 65 ~ 85 | 60 ~ 80 | 75 ~ 100 | 95 ~ 125 |

| D.S. (kg/hr) | 260 ~ 510 | 240 ~ 480 | 300 ~ 600 | 380 ~ 750 | |

| Low Consistency (S.S. 0.8 ~ 1.5%) |

Treating Capacity (m3/hr) | 54 ~ 65 | 50 ~ 60 | 64 ~ 75 | 80 ~ 95 |

| D.S. (kg/hr) | 432 ~ 810 | 400 ~ 750 | 512 ~ 960 | 640 ~ 1200 | |

| Power Consumption(HP) | Driving Motor (Speed Variable) | 2 | 2 | 3 | 3 |

| Disposal Agitator Motor | 3/4 | 3/4 | 3/4 | 3/4 | |

| Drum Thickener | 1 | 1 | 1 | 2 | |

| External Dimensions (Reference)(mm) | L | 6300 | 7000 | 7450 | 7450 |

| W | 3350 | 3000 | 3350 | 3850 | |

| H | 3350 | 3500 | 3650 | 3700 | |

| Base Dimension L1×H1 (mm) | 5150 x 2650 | 5900 x 2900 | 6100 x 3100 | 6100 x 3100 | |

| Base Dimension L2×W1 (mm) | 3350 x 2940 | 4065 x 2440 | 4065 x 2940 | 4065 x 3440 | |

| Reference Weight (kgs) | 4100 | 4300 | 4700 | 5600 | |

Remarks :

|